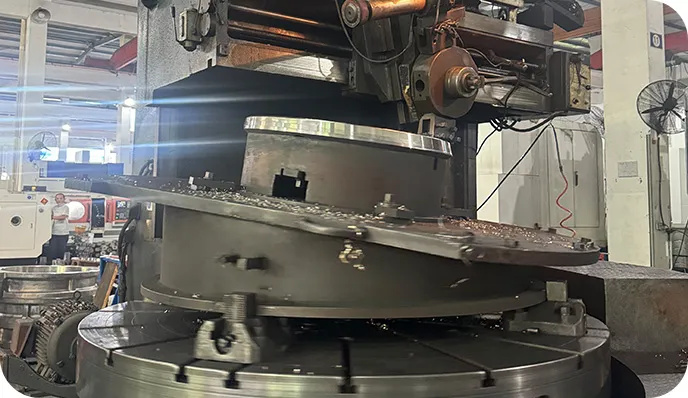

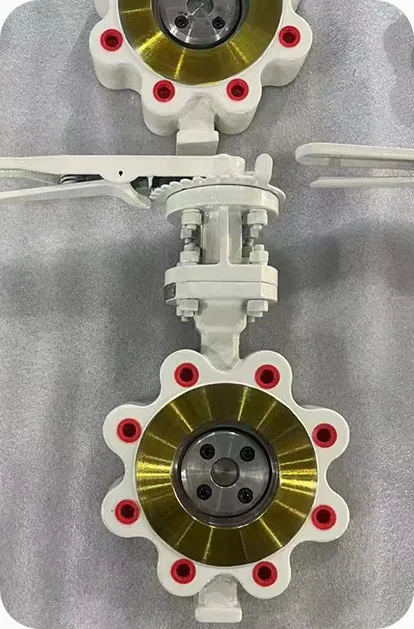

TSV’s commitment to our clients is built on robust industrial valves, crafted from superior materials that pass rigorous quality checks such as impact tests at -60°C and X-ray analysis, ensuring dependable operation.

-The flanged butterfly valve uses flanges(RF, FF, RTJ etc) as the end connection, which has good corrosion resistance and wear resistance, and a long service life.

TSV’s commitment to our clients is built on robust industrial valves, crafted from superior materials that pass rigorous quality checks such as impact tests at -60°C and X-ray analysis, ensuring dependable operation.

The reliability of TSV’s industrial valves is secured through meticulous verification processes, including dimensional and surface defect inspections, ensuring operational longevity and adherence to standards for our clients.

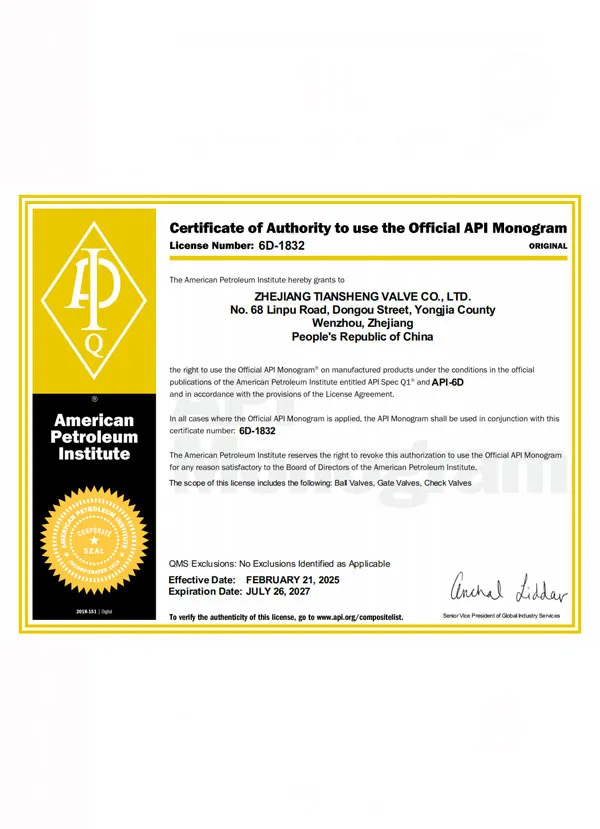

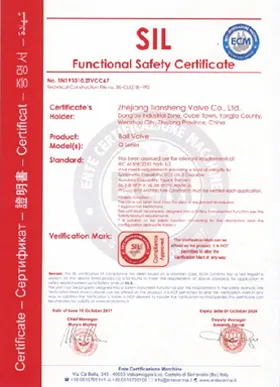

To ensure the operational integrity, our industrial butterfly valves undergo exhaustive performance validation under customized parameters. Each unit is subjected to full compliance testing per international API standards, featuring shell tests at 1.5 times design pressure and bubble-tight seal verification at 1.1 times design. This uncompromising validation protocol distinguishes our products within the competitive landscape of valve manufacturers.

Every valve undergoes a comprehensive pre-shipment audit to verify conformity and finish quality. Our quality team examines surface coatings, dimensional tolerances, packaging integrity, and marking accuracy to guarantee product excellence. This thorough validation process reinforces client confidence and demonstrates our commitment to manufacturing precision.

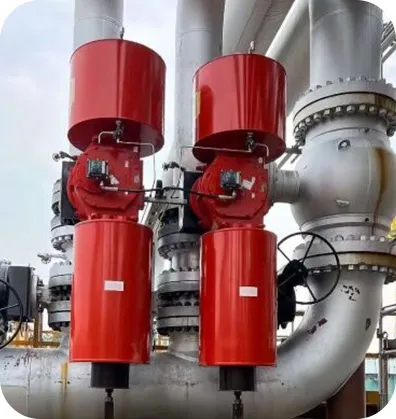

Renowned for engineering high-performance triple offset valves, our solutions deliver exceptional reliability in extreme pressure and temperature environments characteristic of hydrocarbon processing. These specialized valves maintain precise flow regulation for diverse media including natural gas and petroleum products, ensuring operational safety and process efficiency in critical applications.

Within chemical processing systems, triple-offset and high-performance butterfly valve configurations provide critical flow control capabilities. These specialized valves demonstrate exceptional corrosion resistance and sealing performance when managing aggressive media, while their robust construction ensures long-term operational stability in demanding environments.

Within power generation facilities, high-performance butterfly valves serve critical functions in steam and thermal fluid management systems. These specialized valves maintain bubble-tight shutoff and optimized flow characteristics, directly contributing to plant efficiency and operational safety. Our engineered solutions provide reliable performance in demanding power plant applications.

In water infrastructure systems—including supply networks, distribution hubs, and pumping stations—butterfly valves provide essential flow regulation and isolation capabilities. These applications typically utilize double-offset or triple-offset valve configurations for enhanced operational performance.

Cryogenic service valves are specifically engineered for handling liquefied media such as oxygen, nitrogen, and LNG in industrial processes. These specialized valves also find application in fuel gas delivery infrastructure and cryogenic power generation systems including LNG-powered engines and turbine installations.

Within food and beverage processing systems, hygienic-grade butterfly valves are selected for their contamination-resistant properties and clean-in-place compatibility. These valves facilitate efficient sanitation protocols while maintaining product integrity, supporting regulatory compliance and uninterrupted production flow.

When selecting butterfly valves, sealing reliability represents a decisive factor. Our value proposition extends beyond manufacturing to include comprehensive technical support and streamlined maintenance through readily replaceable components. The extended 18-month warranty period—surpassing conventional industry coverage—provides operational assurance, while our strategic inventory of semi-finished components enables rapid 25-day order fulfillment. This integrated approach to customer support establishes new benchmarks in valve supply chain responsiveness.

Butterfly valves function as flow control devices that modulate or isolate the passage of various media—including gases, liquids, and semi-solids—within pipeline networks. Operation is achieved through a rotating disc mechanism that either permits, restricts, or completely obstructs fluid flow.

These components serve critical functions across multiple sectors such as hydrocarbon processing and water management systems. The following analysis examines the technical advantages and operational prevalence of industrial butterfly valves compared to alternative flow control technologies.

Industrial butterfly valves serve as flow regulation devices for both gaseous and liquid media in pipeline applications. These quarter-turn valves operate through a 90-degree disc rotation mechanism that enables full opening or closing positions. Their operational advantages include broad compatibility, dependable performance, and minimal maintenance requirements.

These valves have become integral components across multiple industrial sectors due to their versatile application capabilities. Significant adoption rates are evident in automated systems, water treatment facilities, hydrocarbon processing, chemical production, and hygienic processing industries.

Butterfly valve configurations primarily include wafer-style and lug-type designs for flange mounting applications. Lug-style valves feature external bolt bosses aligned with pipeline flange patterns, enabling direct bolted connections. Conversely, wafer-style valves employ a flangeless design that gets clamped between mating flanges, with fasteners passing completely around the valve body.

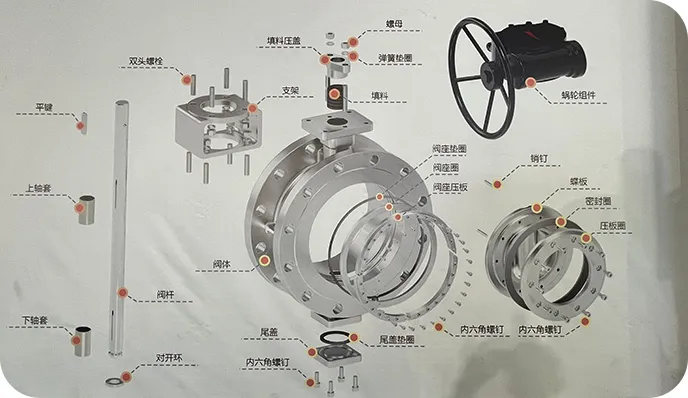

Valve stem configurations may utilize either monolithic or segmented shaft designs. In resilient-seated valves, the stem remains isolated from process media, permitting cost-effective material selection based primarily on mechanical requirements. Conversely, high-performance designs expose the stem to media contact, necessitating corrosion-resistant engineering materials.

Butterfly valves function as flow control devices that modulate or isolate the passage of various media—including gases, liquids, and semi-solids—within pipeline networks. Operation is achieved through a rotating disc mechanism that either permits, restricts, or completely obstructs fluid flow.

Butterfly valves function as flow control devices that modulate or isolate the passage of various media—including gases, liquids, and semi-solids—within pipeline networks. Operation is achieved through a rotating disc mechanism that either permits, restricts, or completely obstructs fluid flow.

Butterfly valves stand out for their compact design and low weight, taking up minimal installation space relative to many other valve types. Their simple operational design allows complete flow control with just a quarter-turn of the actuator, enabling quick open-close functionality. Sourced from a trusted manufacturer, these valves deliver reliable performance, are economical to maintain, and offer excellent long-term value.

A inherent characteristic of butterfly valves is that the disc remains in the flow path even in the open position, which can create a persistent pressure differential across the valve. Their operation also presents potential challenges, such as flow restrictions that may induce cavitation. Furthermore, certain designs can be prone to sealing issues, and their use for throttling is generally most effective in systems with minimal pressure differentials.

Butterfly valves can be categorized according to their body design configurations.

A wafer-design butterfly valve incorporates alignment holes for precise mounting between pipeline flanges. This style is commonly favored in industry due to its lower weight and reduced cost.

Lug-style butterfly valves are characterized by threaded inserts encircling the valve body, enabling direct bolting into a pipeline. A key advantage is their ability to be installed or removed from one section without disrupting adjacent piping. While lug valves can often serve as substitutes for wafer valves, the reverse substitution is typically not feasible.

Flanged butterfly valves are typically produced in larger dimensions and support multiple pipe connection configurations. Their design includes extended rims or flanged ends, allowing for secure bolting between two pipeline segments.

Welded butterfly valves are designed for high-pressure systems where standard connections are insufficient. Unlike plastic-lined valves, which are generally restricted to PN10/16 pressure classes, the welded type is seldom used with non-metallic materials. Consequently, these valves are commonly manufactured using metals such as stainless steel.

Butterfly valves can also be classified based on the geometry of their disc orientation, with common types including zero, double, and triple offset designs.

Zero-offset butterfly valves, commonly referred to as resilient-seated or rubber-seated types, are characterized by a concentric alignment of the stem, disc, and body. This straightforward construction makes them relatively simple to manufacture.

Double-offset butterfly valves, often termed high-performance butterfly valves, are widely employed across numerous industries today. They represent a significant advancement over single-offset designs, offering enhanced operational characteristics and reliability.

Triple-offset butterfly valves build upon the double-offset design by incorporating an additional, third eccentricity. While the first two offsets mirror those of the double-offset type, the third is introduced through an angled cone geometry of the seating surface, enhancing its sealing capabilities.

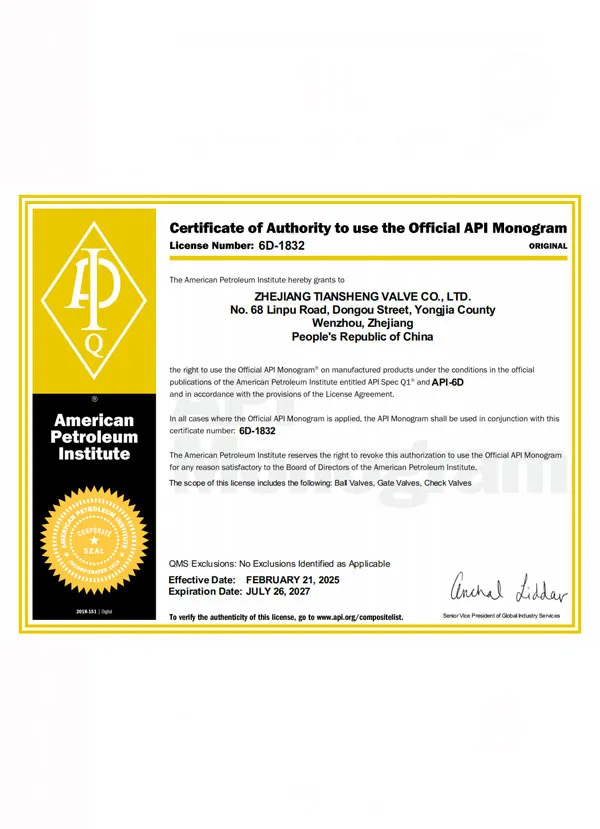

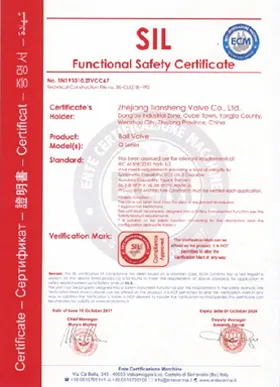

Our offerings are developed in full compliance with global standards and specifications, ensuring that we deliver products and services of the highest reliability and excellence to our customers.

TSV provides custom-engineered industrial valves designed to meet your specific operational requirements and performance criteria. Our products adhere to internationally recognized standards including ISO, API, MSS, and ASME, ensuring superior quality and reliability.

As your trusted industrial valve partner, TSV prioritizes on-time delivery, recognizing that meeting project timelines is critical to our clients' operational success.

TSV maintains ongoing support after product delivery, backed by comprehensive warranties and dedicated customer service to ensure continued satisfaction.

GET A QUOTE

Talk to Our Expert