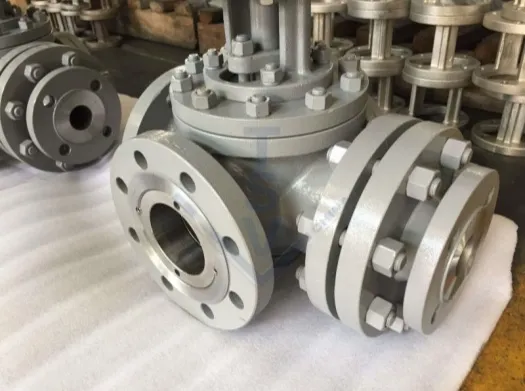

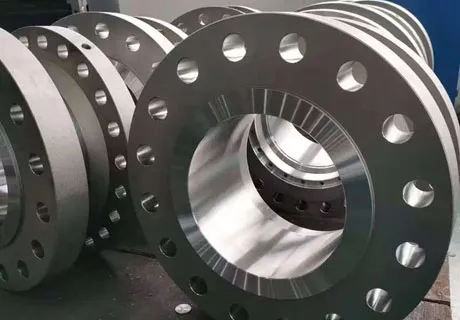

As a type of quarter-turn valve, industrial ball valves utilize a rotating ball with a bore to start or stop media flow with a simple 90-degree turn. They are valued for reliable sealing and ease of operation but are unsuitable for throttling or partially open duties, as uneven pressure can damage internal components.

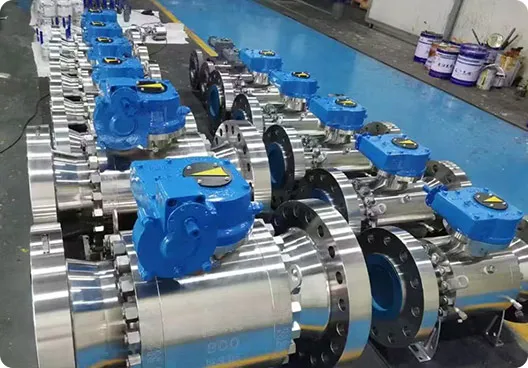

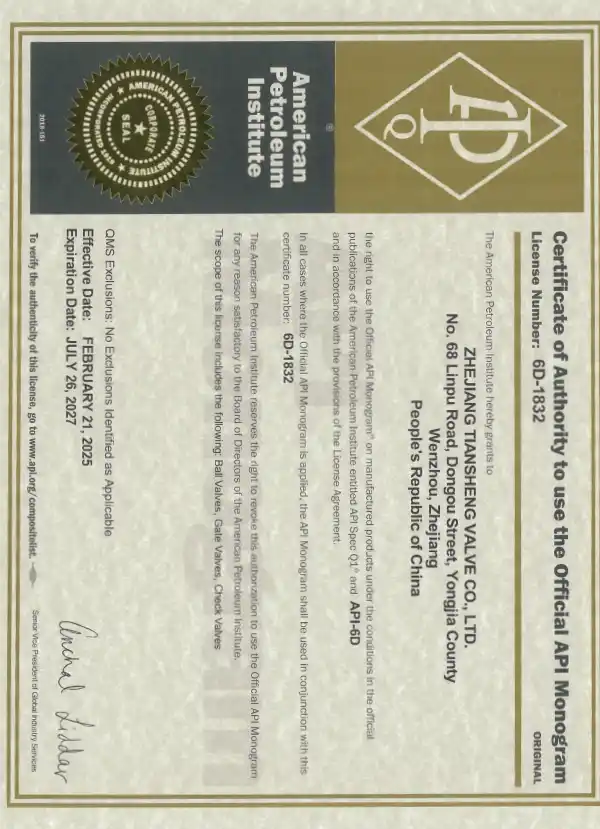

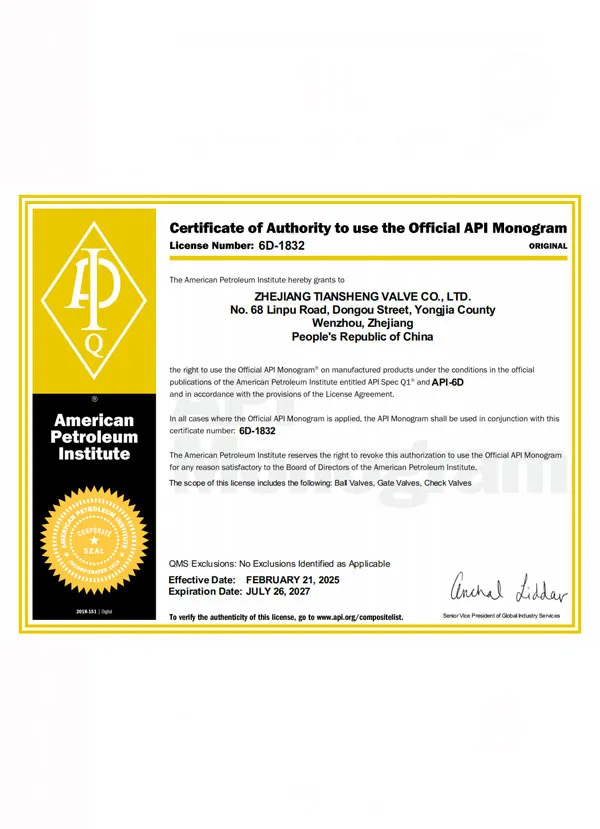

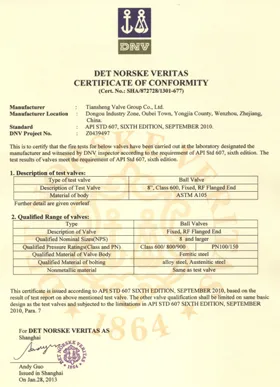

Metal-seated ball valves, in particular, are essential in demanding environments such as chemical processing, mining, and other non-refinery applications involving high pressure, extreme temperatures, abrasion, or corrosive media. This has driven specific demand for durable quarter-turn valves capable of crucial isolation under harsh conditions. Reputable manufacturers like TSV design these valves for rapid actuation, easy restoration, and dependable performance even in severe service situations.