How to Select a Safety Valve

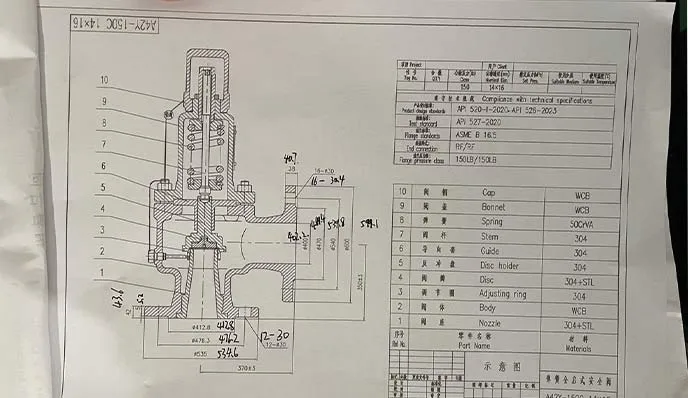

Based on the media (air, gas, steam, liquid).

Set pressure, open pressure, and back pressure.

The valve must be sized based on the required capacity.

Operating conditions—including temperature, medium and environment—must be taken into account during selection.

Based on the operational characteristics.

Normal working pressure is the operating pressure of the system under full load.

The maximum allowable working pressure (MAWP) represents the highest permissible pressure under standard operating circumstances.

Set pressure, it is the pressure at which the valve starts to lift.

Overpressure refers to the amount by which the system pressure surpasses the valve's set point, initiating the lifting process.