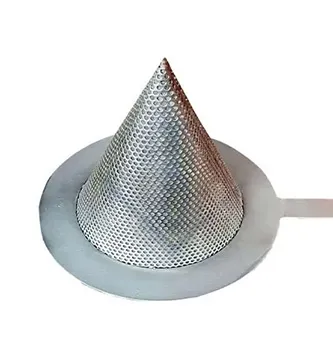

-Strainer is an indispensable filter device in the pipeline system of conveying media. It usually installed at the inlet end of pressure reducing valve, pressure relief valve, fixed level valve or other equipment to remove impurities in the media to protect the normal use of valves and equipment.

Advantage

1. High efficiency, precise filtration: special structure of filter disk filtration technology, precise and sensitive performance;

2. Long life: the new filter element is sturdy, non-abrasive, non-corrosive, and rarely scales, which has been verified by many years of industrial practice, and the filtration and backwashing effect will not deteriorate due to the use of time;

3. High quality and low maintenance;

Characteristic

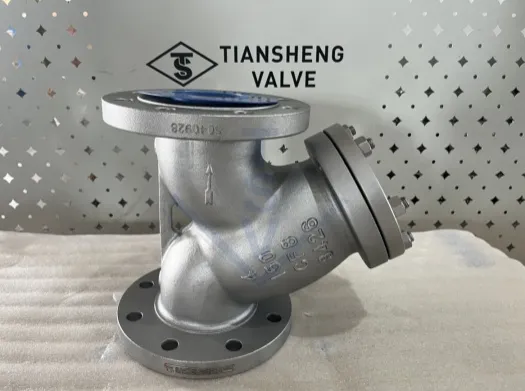

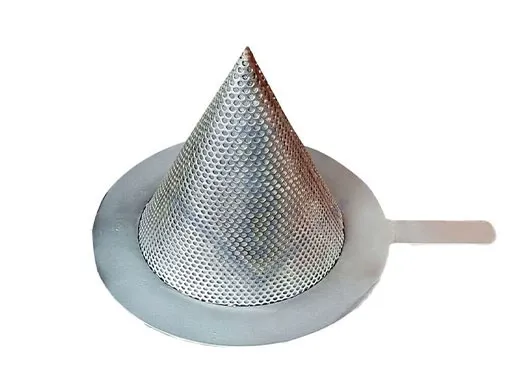

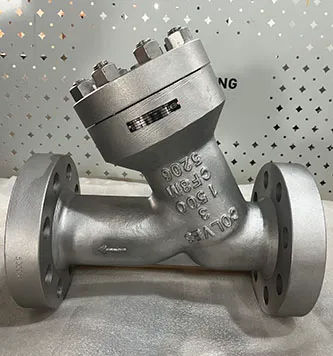

Filters are divided into Y-type filters, basket filters, T-type filters and conical filters; they are called by different names because of their different shapes;