A Super Duplex Trunnion Ball Valve is a high-performance, heavy-duty industrial valve engineered for the most demanding applications in aggressive and corrosive environments. It combines the superior mechanical and corrosion-resistant properties of super duplex stainless steel with the robust trunnion-mounted ball design.

Product Details

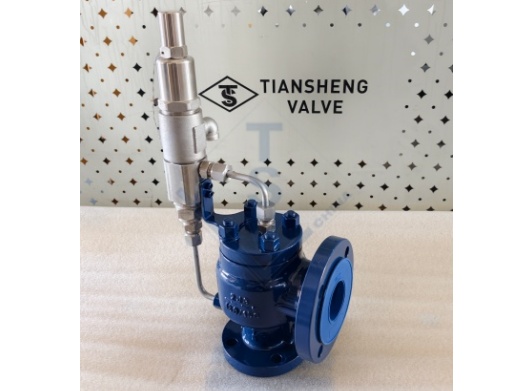

Ball Valve 12" Material Super Duplex

TRUNNION MOUNTED BALL VALVE 12" DESIGN: API 6D,

FIRE SAFE API 607,

CLASS 150 LB,

END CONNECTION: RF ASME B16.5 DIMENSION AS PER ASME B16.10, INSPECTION AND TEST AS PER API 598, BODY/BONNET: SUPER DUPLEX ASTM A890 5A,

BALL: DUPLEX ASTM A182 F51+NI60,

STEM DUPELEX ASTM 182 F51,

SEAT: DUPLEX A182 F51+NI 55,

METAL SEATED, OPERATION:

GEAR, INCLUDING 2 FLUSHING HOLES, DWG.NO: 16081956

Key Features & Advantages:

-

Super Duplex Stainless Steel Construction

-

Material Excellence: The valve body, trim, and critical components are manufactured from super duplex stainless steel, which offers:

-

Exceptional Corrosion Resistance: Highly resistant to pitting, crevice corrosion, and stress corrosion cracking (SCC), especially in chloride-containing environments.

-

High Strength: Yield strength is approximately twice that of standard 316 stainless steel, allowing for lighter and more compact valve designs with higher pressure ratings.

-

Excellent Erosion Resistance: Ideal for applications with high flow velocities or abrasive media.

-

-

-

Trunnion-Mounted Ball Design (The Core Feature)

-

Fixed & Supported Ball: Unlike floating ball valves, the ball is anchored and supported at the top and bottom by trunnion pins (shafts). This design is crucial for handling high pressures (Class 600 to 2500 and above) and large diameters (typically 2" and larger).

-

Reduced Operating Torque: The trunnions bear the hydraulic load from line pressure, minimizing friction between the ball and seats. This results in significantly lower operating torque, enabling the use of smaller, more economical actuators.

-

Reliable Sealing & Blow-Out Prevention: The fixed ball and downstream sealing mechanism ensure bi-directional sealing capability. The trunnion design prevents stem blow-out under high-pressure conditions, enhancing safety.

-

-

Enhanced Sealing Technology

-

Fire-Safe Design: Valves are typically compliant with API 607/ISO 10497 fire-safe standards. In a fire, secondary metal-to-metal seals engage to maintain a seal and prevent catastrophic failure.

-

Anti-Static & Anti-Blowout Stem: A spring mechanism ensures electrical continuity between the stem and body to prevent static charge buildup. The stem is securely locked to prevent ejection.

-

Request a Quote

Request a Quote