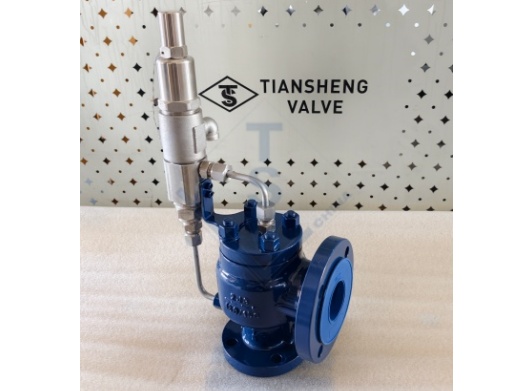

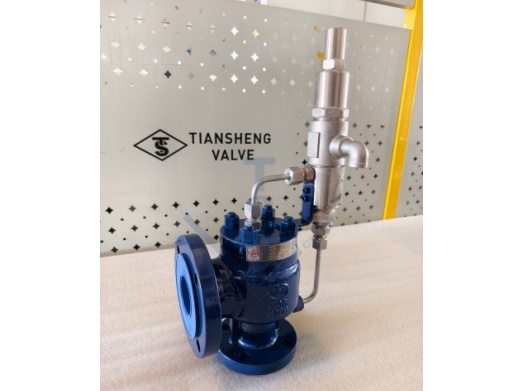

A Pilot-Operated Safety Valve is a high-performance pressure relief device that utilizes system pressure itself to control the opening and closing of the main valve. Unlike conventional spring-loaded valves, it employs a smaller, integrated "pilot" valve to actuate a much larger main valve. The "Full-Lift" designation indicates that the main valve disc opens completely at set pressure, providing maximum flow capacity for rapid overpressure protection. This design is renowned for its excellent tightness, high capacity, and operational flexibility.

Product Details

Technical Overview: Pilot-Operated Full-Lift Safety Valves

The Pilot-Operated Full-Lift Safety Valve represents a sophisticated and highly efficient solution for overpressure protection in demanding industrial applications. Its operation is based on a two-stage process involving a pilot valve and a main valve.

Core Operating Principle:

-

In a "Closed" Position: System pressure is routed to the top of the main piston (or diaphragm) through the pilot valve. Because the area on top of the piston is greater than the area exposed to inlet pressure at the bottom, the net force holds the main valve tightly shut. This design provides exceptional bubble-tight sealing up to very close to the set pressure, minimizing fugitive emissions and product loss.

-

At "Set Pressure": The pilot valve, which is a small, precision spring-loaded valve, opens when the system pressure reaches the set point. This action relieves the pressure from the top of the main piston.

-

"Opening" Sequence: Once the pressure above the piston is released, the system pressure acting on the larger area underneath the piston creates a substantial net upward force. This forces the main valve to pop open to its full-lift position almost instantaneously. The large flow path allows for a high discharge capacity.

-

"Re-seating": When the system pressure drops to a predetermined closing pressure (typically higher than that of a spring-operated valve), the pilot valve closes. Pressure then rebuilds on top of the main piston, forcing it back down onto the seat and shutting the main valve firmly.

Key Advantages & Features:

-

Exceptional Tightness: Can achieve bubble-tight sealing up to 97-99% of set pressure, far superior to spring-loaded valves. This is critical for conserving valuable, hazardous, or expensive media.

-

High Capacity & Full-Lift Performance: The powerful piston-actuated opening provides a large, unobstructed flow path, making these valves ideal for applications requiring the relief of large volumetric flow rates.

-

Reduced Chattter & Stability: The controlled, non-impact opening and closing action significantly reduces the risk of "chatter," a destructive phenomenon common in spring valves, thereby enhancing valve longevity and system stability.

-

Flexibility: Pilots can often be configured for various functions, such as modulating flow, remote operation, or testing without taking the main valve offline.

-

Suitability for High Pressure: Excellent performance in high-pressure systems where spring-loaded valves can suffer from large, variable spring forces.

Request a Quote

Request a Quote