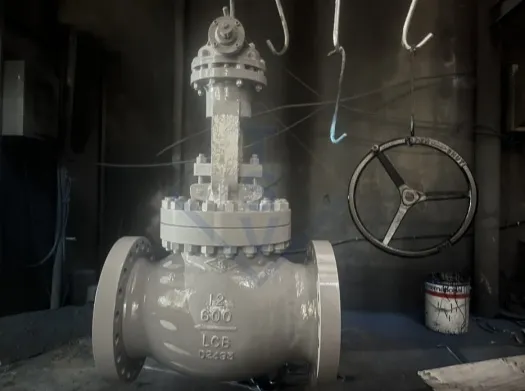

A Forged Dual-plate Check Valve, also commonly known as a Butterfly Check Valve or a Wafer-type Dual-plate Check Valve, is a compact, lightweight, and highly efficient valve designed to prevent reverse flow (backflow) in a piping system. Its name is derived from its two spring-loaded, hinged plates (or discs) that open and close in response to fluid flow.

Product Details

Key Features & Advantages:

-

Compact & Lightweight Design: Its wafer-style body fits snugly between pipe flanges, requiring minimal space and reducing overall weight and support structure costs. This makes it significantly smaller and lighter than a conventional swing check valve.

-

Forged Body Construction:

-

Superior Strength: Forging aligns the metal grain structure, resulting in higher strength, better fatigue resistance, and greater toughness.

-

Enhanced Safety: Ideal for high-pressure, high-temperature, and critical applications where reliability is paramount (e.g., power generation, offshore platforms).

-

Better Surface Finish: Forged components generally have a denser structure with fewer internal imperfections like porosity or shrinkage cavities.

-

-

Rapid Response & Low Water Hammer: The plates are assisted by torsion springs, which ensure quick, positive closing before reverse flow can fully develop. This significantly reduces the risk of water hammer, protecting the entire piping system.

-

Low Pressure Drop: When fully open, the two plates position themselves parallel to the flow, offering minimal flow resistance and thus a very low pressure drop across the valve. This improves system efficiency and reduces pumping costs.

-

Automatic Operation: The valve is self-actuating. It opens with forward flow pressure and closes automatically using spring force and reverse flow when the upstream pressure decreases.

Typical Applications:

-

Power Plants: Main steam lines, feedwater systems, cooling water systems.

-

Oil & Gas Industry: Pipeline transport, offshore production facilities, refinery processes.

-

Chemical & Petrochemical Plants: Handling various process fluids where backflow prevention is critical.

-

Marine & Shipbuilding: Seawater cooling, firefighting, and ballast systems.

-

Water & Wastewater Treatment: Pump discharge lines.

Summary of Benefits:

-

Compact, space-saving design

-

High strength and reliability from forged construction

-

Fast closing action, minimizing slam and water hammer

-

Low pressure drop for energy efficiency

-

Lightweight, reducing structural support needs

-

Suitable for a wide range of pressures and temperatures

Request a Quote

Request a Quote