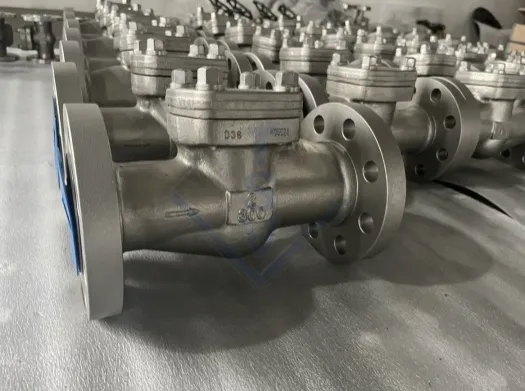

The Forged Swing Check Valve is a widely used type of check valve designed to allow fluid flow in one direction while preventing backflow in the opposite direction. It features a disc that swings on a hinge or pivot, opening when fluid flows in the correct direction and closing when flow stops or reverses. This simple yet effective design makes swing check valves suitable for a variety of applications, particularly in systems with low to moderate flow velocities.

Product Details

Key Specifications:

Size: 1”

Pressure: 150LB

Standard Compliance: api 6d, api594, asme b16.5 or equivalents

Materials: carbon steel, stainless steel or other specials.

End connections: flanged (rf, rtj, ff), welded, thread, wafer .

Api trim #1,#5, #8, #10 and etc

Key Features:

-

Swinging Disc Design:

-

The valve uses a disc that swings open on a hinge or pivot when fluid flows in the correct direction.

-

When flow stops or reverses, the disc swings back to its closed position, preventing backflow.

-

-

Low Pressure Drop:

-

When fully open, the disc moves out of the flow path, minimizing pressure drop and turbulence.

-

-

Simple and Reliable Operation:

-

The swinging disc design is straightforward, with no springs or complex mechanisms, making it reliable and easy to maintain.

-

-

Durable Construction:

-

Constructed from materials such as stainless steel or carbon steel, swing check valves are designed to withstand high pressures, temperatures, and corrosive environments.

-

-

Suitable for Horizontal and Vertical Installation:

-

Swing check valves can be installed in both horizontal and vertical pipelines, provided the disc can swing freely to close.

-

Request a Quote

Request a Quote