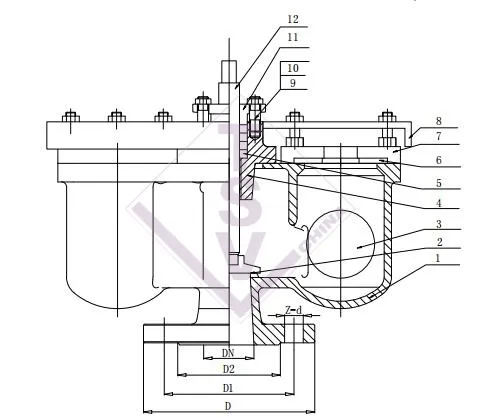

A Double Chamber Air Release Valve is an advanced automatic valve designed to efficiently expel accumulated air or gases from pressurized liquid systems while maintaining pipeline integrity. It combines two functional chambers to handle both large-volume air release (during filling/draining) and fine air bleed (during operation), ensuring optimal system performance.

Product Details

Key Features:

-

Automatic Air Release – Expels trapped air during system operation to maintain optimal flow.

-

Vacuum Protection – Admits air to prevent pipeline collapse during drainage or negative pressure.

-

High-Pressure Tolerance – Robust design withstands varying pressure conditions.

-

Durable Construction – Typically made of corrosion-resistant materials (e.g., stainless steel, or epoxy-coated iron).

-

Low Maintenance – Self-acting mechanism reduces manual intervention.

Key Functions:

1. Dual-Chamber Design:

- Large Orifice (Main Valve): Rapidly releases large air pockets during system startup or shutdown.

- Small Orifice (Auxiliary Valve): Continuously vent trapped during normal operation.

2. Critical Applications:

- Water supply pipelines, sewage systems, irrigation networks, and industrial fluid transport.

- Prevents air-related issues like water hammer, corrosion, flow reduction, and pump cavitation.

3. Advantages:

- Enhanced Safety: Protects pipelines from pressure surges.

- Energy Efficiency: Maintains steady flow, reducing pump workload.

-Durability: Constructed from corrosion-resistant materials.

Installation & Maintenance:

- Mounted at pipeline high points or critical air accumulation zones.

- Periodic inspection ensures seals and moving parts remain debris-free.

Request a Quote

Request a Quote