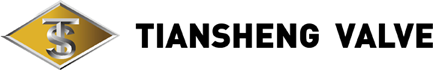

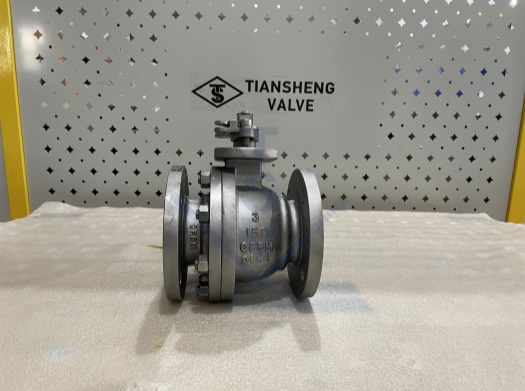

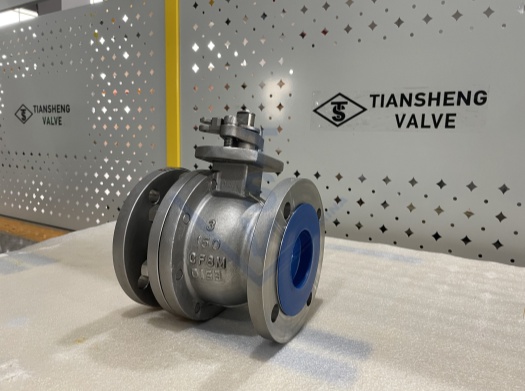

The Cast Steel Floating Ball Valve is a robust and reliable industrial valve designed for a wide range of applications in industries such as oil and gas, petrochemical, power generation, and water treatment. Constructed from high-quality cast steel, this valve offers excellent strength, durability, and resistance to high pressures and temperatures. The floating ball design ensures tight sealing and efficient operation, making it suitable for both on/off and throttling applications.

Product Range:

Size: 1/2" - 10" (DN15 - DN250)

Class: 150LB, 300LB (PN1.6 - PN4.0)

Body Material: A216 WCB/ WCC, A352 LCB/ LCC, A351 CF8/ CF3/ CF8M/ CF3M, A890 4A/ 5A...

Trim Material: A105+ENP, 13CR, SS304/ SS316, F304/ F316...

Seat & Seals: PTFE, R-PTFE, NYLON, DEVLON, PEEK...or Metal Sealing

Operation: Lever/ Wrench, Gear, Pneumatic/ Electic Actuator...

Key Features:

-

Cast Steel Construction: The valve body and key components are made from cast steel, which provides excellent mechanical properties, including high strength, toughness, and resistance to impact and fatigue. This makes the valve suitable for high-pressure and high-temperature environments.

-

Floating Ball Design: The ball is not fixed in place and is free to move slightly within the valve body. When the valve is closed, the pressure of the fluid pushes the ball against the downstream seat, creating a tight seal. This design ensures reliable sealing and is particularly effective for low-to-moderate pressure applications.

-

Bi-directional Sealing: The valve provides effective sealing in both directions, ensuring leak-proof operation regardless of the flow direction.

-

Durable Sealing Materials: The seats and seals are made from high-performance materials such as PTFE, reinforced PTFE, or metal, depending on the application. These materials provide excellent sealing performance and long service life, even in corrosive or high-temperature environments.

-

Fire-safe Design: Many cast steel floating ball valves are designed to be fire-safe, meaning they can maintain their integrity and prevent leakage even in the event of a fire.

-

Blowout-proof Stem: The stem is designed to prevent blowout, ensuring safe and reliable operation under high-pressure conditions.

-

Versatile End Connections: The valve is available with various end connections, including flanged, threaded, and welded ends, to suit different piping systems and installation requirements.

-

Compact and Lightweight Design: Compared to trunnion-mounted ball valves, floating ball valves are generally more compact and lightweight, making them easier to install and suitable for applications where space and weight are considerations.

Advantages:

-

High Strength and Durability: The cast steel construction provides excellent strength and durability, making the valve suitable for high-pressure and high-temperature applications.

-

Reliable Sealing: The floating ball design ensures tight sealing, preventing leakage and ensuring efficient operation.

-

Versatile Applications: The valve is suitable for a wide range of applications, including oil and gas, petrochemical, water treatment, and chemical processing.

-

Easy Operation: The floating ball design requires relatively low operating torque, making the valve easy to operate.

-

Easy Maintenance: The design allows for easy maintenance and repair, minimizing downtime and operational costs.

Request a Quote

Request a Quote