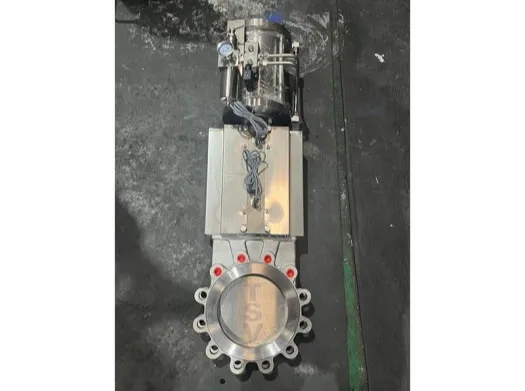

The Knife Gate Valve with Replaceable Rubber Seat is a highly efficient and versatile valve designed for handling abrasive, viscous, and slurry-based media in demanding industrial applications. This valve features a knife gate mechanism that cuts through thick and heavy materials, ensuring smooth operation and minimal clogging. The replaceable rubber seat provides excellent sealing performance and allows for easy maintenance, reducing downtime and operational costs. Ideal for industries such as mining, wastewater treatment, pulp and paper, and chemical processing, this valve offers durability, reliability, and cost-effectiveness.

Product Details

Key Specifications:

Sizes: 2″ – 48″ or DN 50 – DN 1200

Pressure Rating: Class150 or PN6 – PN16

Materials of valve body: WCB, LCB, WC6, CF8, CF3, CF8M, CF3M, 4A, etc.

Operation: Manual, Gear, Pneumatic, hydraulic and Electric actuator

Features:

Bi-direction design

Replaceable Rubber seat, Bubble-tight seat seal

Self-cleaning mechanism

Rising stem or Non-rising stem

Wafer Lugged body

Design & Manufacture:

MSS SP-61, ASME 16.34

Face to Face: MSS SP-81, ASME B16.10, EN 558

Connection End: ASME B16.5, EN 1092, JIS B2220

Test : MSS SP-81

Key Features:

Knife Gate Mechanism:

-

Efficient Cutting: The sharp-edged gate is designed to cut through thick, viscous, and abrasive media, such as slurries, sludge, and solids.

-

Minimal Clogging: The knife gate design reduces the risk of clogging, ensuring smooth operation even in challenging applications.

Replaceable Rubber Seat:

-

Easy Maintenance: The rubber seat can be easily replaced when worn, reducing downtime and maintenance costs.

-

Excellent Sealing: The rubber seat provides a tight, bubble-tight seal, minimizing leakage and ensuring reliable performance.

-

Versatility: Suitable for a wide range of temperatures and media, depending on the type of rubber used (e.g., EPDM, NBR).

Request a Quote

Request a Quote